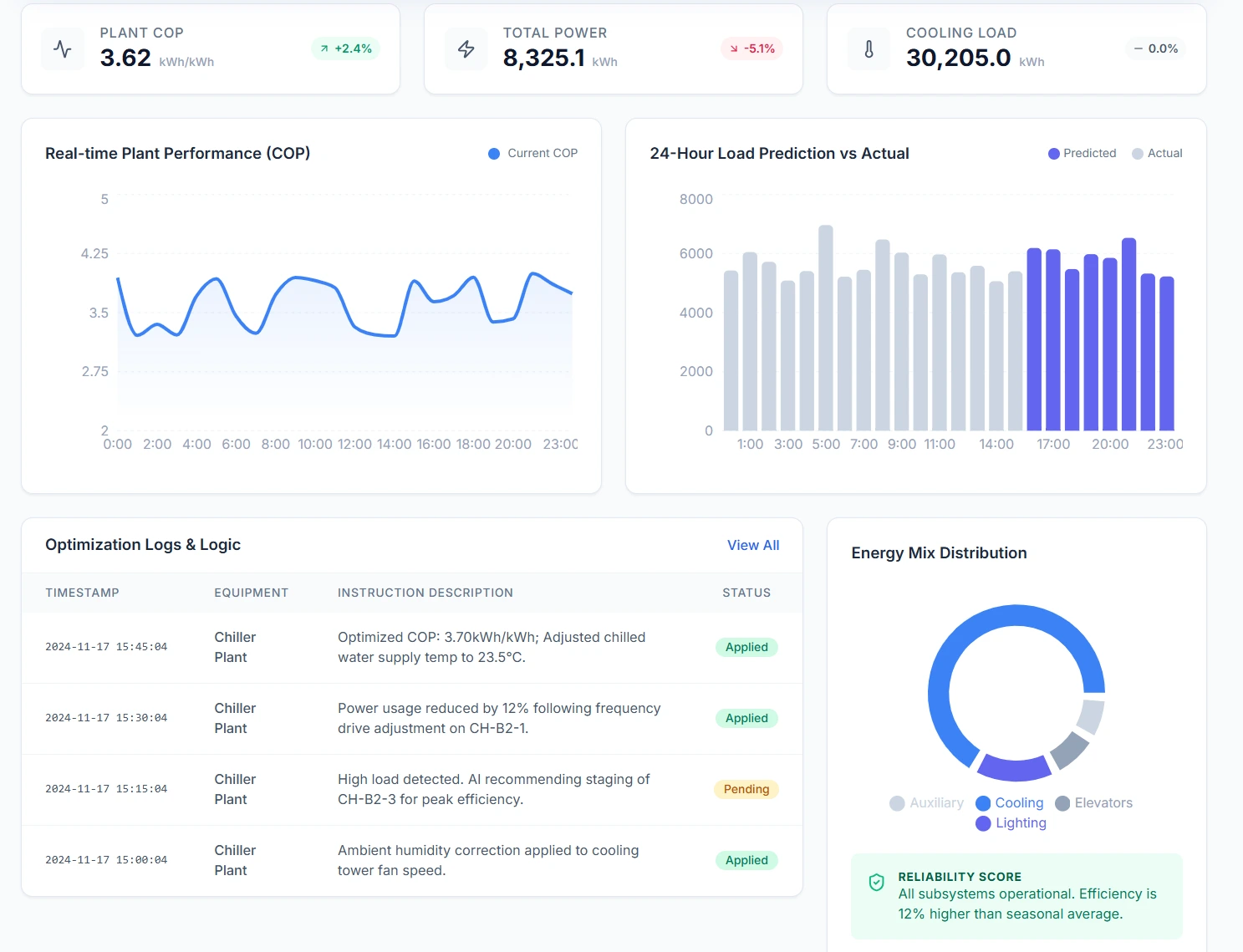

Smarter Cooling, Lower Energy

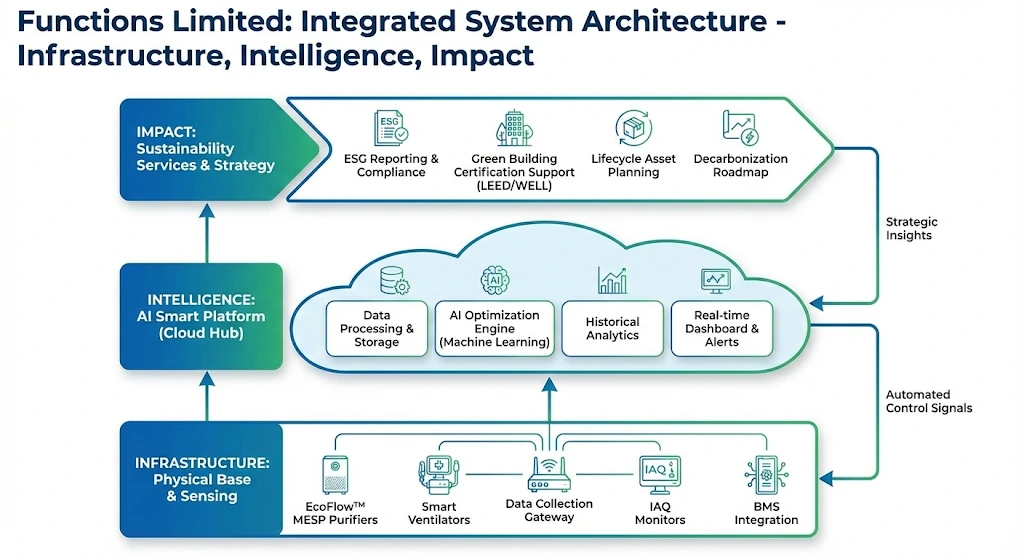

An intelligent control brain for central chiller plants. By learning from operational data, it dynamically adjusts chillers, pumps, and cooling towers to maintain comfort while cutting energy use and carbon emissions.

The Intelligence Loop

A closed-loop 'Perception – Prediction – Decision – Optimization' model that continuously fine-tunes operation to achieve peak system efficiency.

Perception

Real-time data collection & load monitoring

Prediction

Forecasting weather & equipment performance

Decision

Calculating optimal staging & setpoints

Optimization

Automated execution & feedback

Deep Energy-Saving Mechanism

Intelligent coordination delivers 8–10% total plant energy savings by targeting the three core components.

Chillers

Neural network optimization based on COP & load rate.

Optimizes outlet temp (+1–2℃)

Water Pumps

AI frequency optimization + VFD control.

Eliminates 'small temp difference' syndrome

Cooling Towers

Joint optimization of fan & pump efficiency.

Lowers approach temp (-1°C)

AI-Driven Small Models

Simulates performance using minute-level data to recommend precise operational settings.

Self-Learning Architecture

Combines neural networks and expert rules, improving accuracy automatically over time.

Plug-and-Play Integration

Seamlessly compatible with existing BMS and IoT protocols (BACnet, Modbus, MQTT).

Quantifiable Results

Transforms traditional systems into intelligent networks, delivering measurable electricity cost reductions.

Proven Results

Fresenius Kabi (Phase 4): System efficiency improved from 4.21 to 4.83 within just four months.

Fresenius Kabi (Pharma): Two chiller plants saved ~RMB 2M annually in electricity costs.

Shanghai Hines 1MP: Achieved immediate savings during the initial AI deployment phase.

Metro China: IoT integration enabled 100% paperless operation and optimized maintenance staffing.